Ideal Spectroscopy is looking for a staff research scientist with skills needed to build external cavity diode laser (ECDL) prototype devices using modern diode lasers and to extend wavelength coverage in the blue/green regions of the spectrum. These devices will advance scientific research adding capabilities that are not available currently as most commercially ECDLs are restricted to the red and near-infrared. A list of skills and qualifications are shown below. This staff scientist position will become permanent to qualified candidates who are productive, we encouraged you to apply.

Most commercially available high-resolution tunable external cavity diode lasers available today have output wavelengths restricted to the red and near-infrared wavelengths. However, many new commercially available Fabry-Perot laser diodes can be purchased that emit in the orange, yellow, green and even blue wavelength regions of the spectrum. Certain conditions are required to allow these new diode lasers to be used in an external cavity. One main requirement is that the output facet has a quality anti-reflective (AR) coating, ideally as low as 0.1% reflectivity. The high AR coating allows for the diode laser to operated at high-current without reaching its internal lasing threshold, it will not lase from the weak feedback reflecting off its front facet. This condition is ideal, so that feedback from the grating, will form an external cavity component and allows single-mode operation along with wavelength tunability.

Fabry-Perot (FP) Laser Diodes

The simplest type of semiconductor laser is the Fabry-Perot (FP) laser diode where the output power and wavelength are tunable by altering the diode temperature and/or current. In these devices, two parallel ends of the semiconductor are cleaved along the crystal axis, creating reflective mirrors forming a Fabry-Perot laser cavity across the semiconductor gain medium material, such as GaN, InGaN, AlGaAs, InGaAsP, AlGaInP, etc. Optical coatings are typically applied to the mirror facets to optimize the output power, with the laser emission taken from the low-reflectivity front facet and high-reflectance on the back facet to reduce the overall mirror loss. The gain spectrum of the semiconductor medium is quite broad and supports lasing over many longitudinal modes of the FP cavity. Consequently, FP laser diodes typically operate with multiple longitudinal modes. The longitudinal mode spacing is determined by Delta v = c/2nL, where c is the speed of light, L is the laser diode chip length, and n is the group index of refraction of the semiconductor waveguide. This multimode structure of the FP diode laser can be measured directly on an optical spectrum analyzer.

To streamline our prototype development productivity, we could purchase commercially available stock FP laser diodes which emit in the blue/green regions of the spectrum. One possible solution would be to add the needed AR coating to the front facet as a modification. The process would require opening the diode laser packaging, for example, removing the top cover of the T0-CAN, and mounting the diode laser in an optical coating system where physical vapor deposition (PVD) would be used to evaporate the coating materials. Below is a list of publications that outline similar techniques to apply an AR coating along with methods to quantify the film thickness and resulting reflectivity from the front facet. With this process lead time and cost to procure AR coated laser diodes in the visible region would no longer be a barrier to our advancement in ECDL product development.

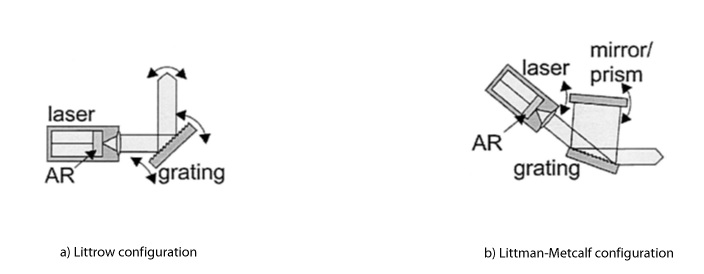

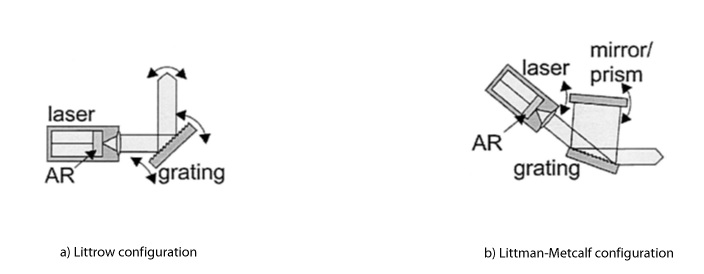

One of the most common cavity arrangements used in commercial ECDLs is the Littman-Metcalf configuration, with one benefit that the output beam is fixed in its direction, it does not move as the wavelength is tuned. This is because the mirror/prism is rotated to change the output wavelength instead of the grating. This configuration also exhibits a smaller linewidth, as the wavelength selectivity is stronger, since the feedback is bounced twice off the grating per resonator round trip. One disadvantage of the Littman-Metcalf configuration is the output power is lower than the Littrow because the zero-order reflection of the beam reflected by the tuning mirror is lost. For this reason, we might consider implementing the Littrow configuration in some of our blue/green ECDL designs when efficiency and output power are low. In these cases, we might consider adding a mechanical motorized mirror system to maintain the pointing stability of the output beam as the grating is angle tuned to change the wavelength.

|

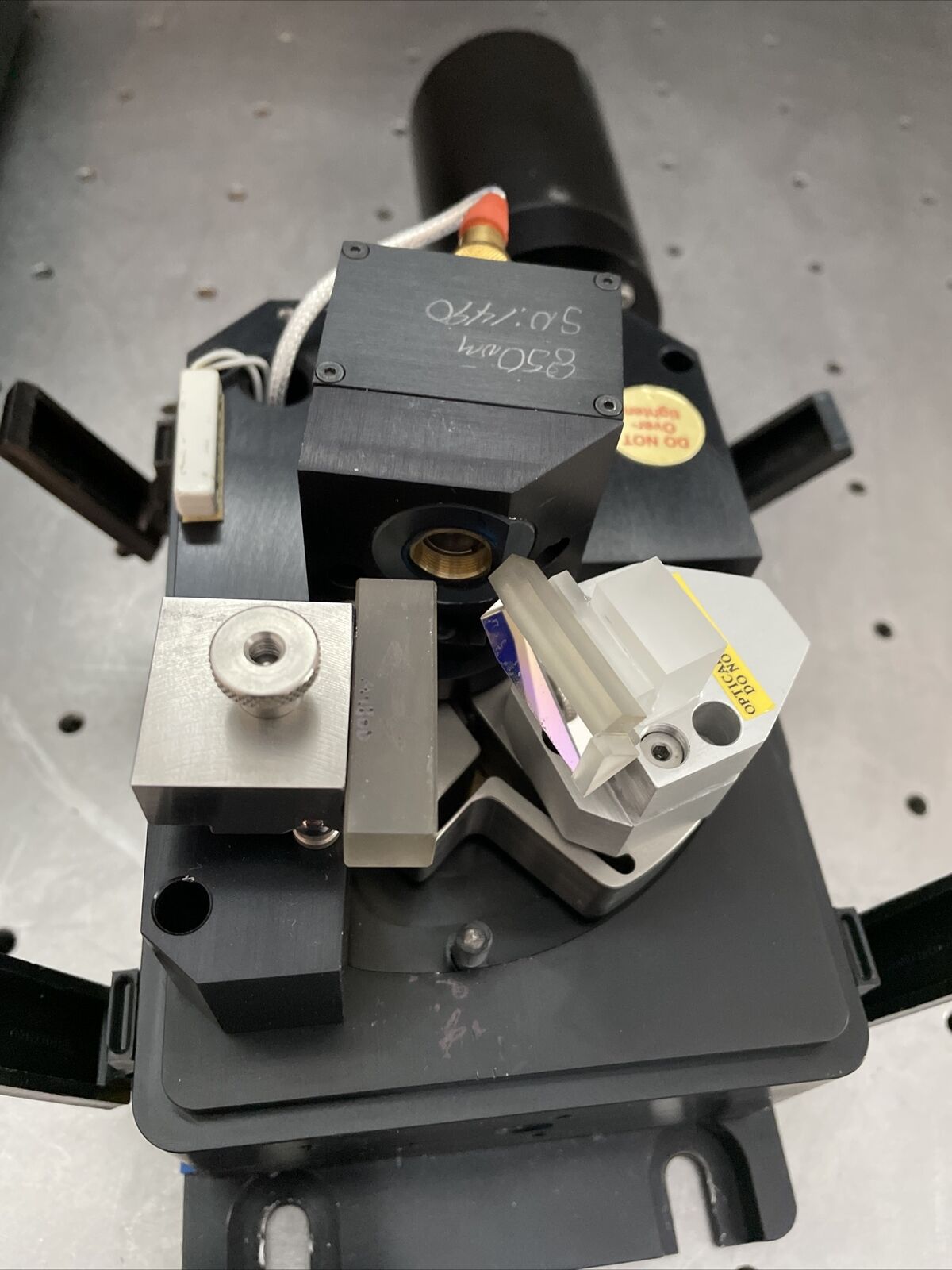

We might envision that our final product could be similar to that shown in the next photograph. It would be advantageous to our customers to allow them to swap diode modules so that they can change the wavelength of their ECDL system. We would need to also offer gratings with different groove densities to provide the correct dispersion and generate the needed optical feedback. A single controller could be offered that manages the diode laser current, the output wavelength, and power of the ECDL. This package could provide a stable laser diode system that is highly versatile with a long operating life and be beneficial to many research and commercial applications.

Skills and Experience:

- Experience designing and building ECDL prototypes

- Experience working with and soldering connections to electrostatic sensitive laser diodes

- Experience working with small thermoelectric cooling (TEC) devices to provide temperature control of the laser diode

- Knowledge collimating diode laser beams to obtain good beam quality

- SolidWorks 3D CAD modeling experience is important

- Able to design prototype, assemble, and test laser devices

- Setup experiments to test and evaluate lasers concepts

- Knows how to use common optics laboratory equipment, oscilloscopes, function generators, lock-in amplifiers, piezos, photodiodes, data acquisition equipment, along with CW and Pulsed laser systems

- Comfortable communicating and sourcing optics and crystal material suppliers

- Maintain and prepare detailed research reports

- Able to write computer programs to automate and collect experimental data. We typically use Visual Studios: VB.net, C# and others

A qualified candidate will have experience operating, setting up experiments, and hands-on tuning/alignment of these types of laser systems. They will have ablilities and experience to excel at collecting data to continue improving the product development.

Ideal Spectroscopy operates a full CNC machine shop, and we are constantly designing new components to improve the capabilities of our spectroscopy products. We are seeking candidates with experience in designing and implementing new laser devices.

Qualifications

- Position open to U.S. citizens and permanent residents

- Ph.D. in Physics, Optical Sciences, Chemistry, or Chemical Physics.

- Hands-on experience conducting advanced laser experiments is required.

- Confident experimentalist, able to setup experiments, tune and align high-resolution cw lasers, collect quality data, and rationalize to improve the prototype

- Aptitude for designing new laboratory instruments

- The ideal candidate will enjoy the thrill of discovery and the intellectual satisfaction of untangelling complex laser development chanllenges

- Able to multitask, maintain laser experiments and collect quality data, while also doing other tasks, such as data analysis and report preparation

Package:

- Salary is negotiable

- BCBS Health Care

- Dental & Vision

- 401K Retirement Package

- Paid vacation, statutory holidays, and sick leave

- Relocation compensation is available

- For the right candidate, this job could evolve into a staff Resarch Scientist position at Ideal Spectroscopy

How To Apply

Please email resume to workwithus@idealvac.com

By Regular Mail To:

Ideal Vacuum Products

Human Resources

5910 Midway Park Blvd NE

Albuquerque, NM 87109

Phone: (505) 872-0037

Fax: (505) 872-9001

Thank you!

Selected Research Publications: