This is our Space Simulation

ExploraVAC TVAC thermal vacuum test chamber system. It mimics the extreme pressures and temperatures of outer space, with pressures down to 10

-7 Torr and sample temperatures from -70 to +225 °C, accurate to ± 0.3 °C, via a 23” × 23” thermally isolated platen. It is a fully integrated, turnkey, high vacuum system featuring a large 24 inch cube welded stainless-steel vacuum chamber, a hinged stainless steel door with viewport, and a volume of 8.0 cubic feet.

The system includes a Pfeiffer HiPace 300 turbomolecular pump, and an Edwards nXR30i dry roots vacuum pump. This system includes two Convectron, a micro-ion, and a piezo-electric vacuum pressure gauge to provide feedback to the user and for the logic controller. An internally regulated purge gas port allows introduction of user-selected gases into the chamber for high-purity or oxygen-and-water-free work.

This Space Simulation

ExploraVAC TVAC system weighs 1302 lb. and requires single-phase 208-240 VAC, 50/60 Hz, at 49 Amps.

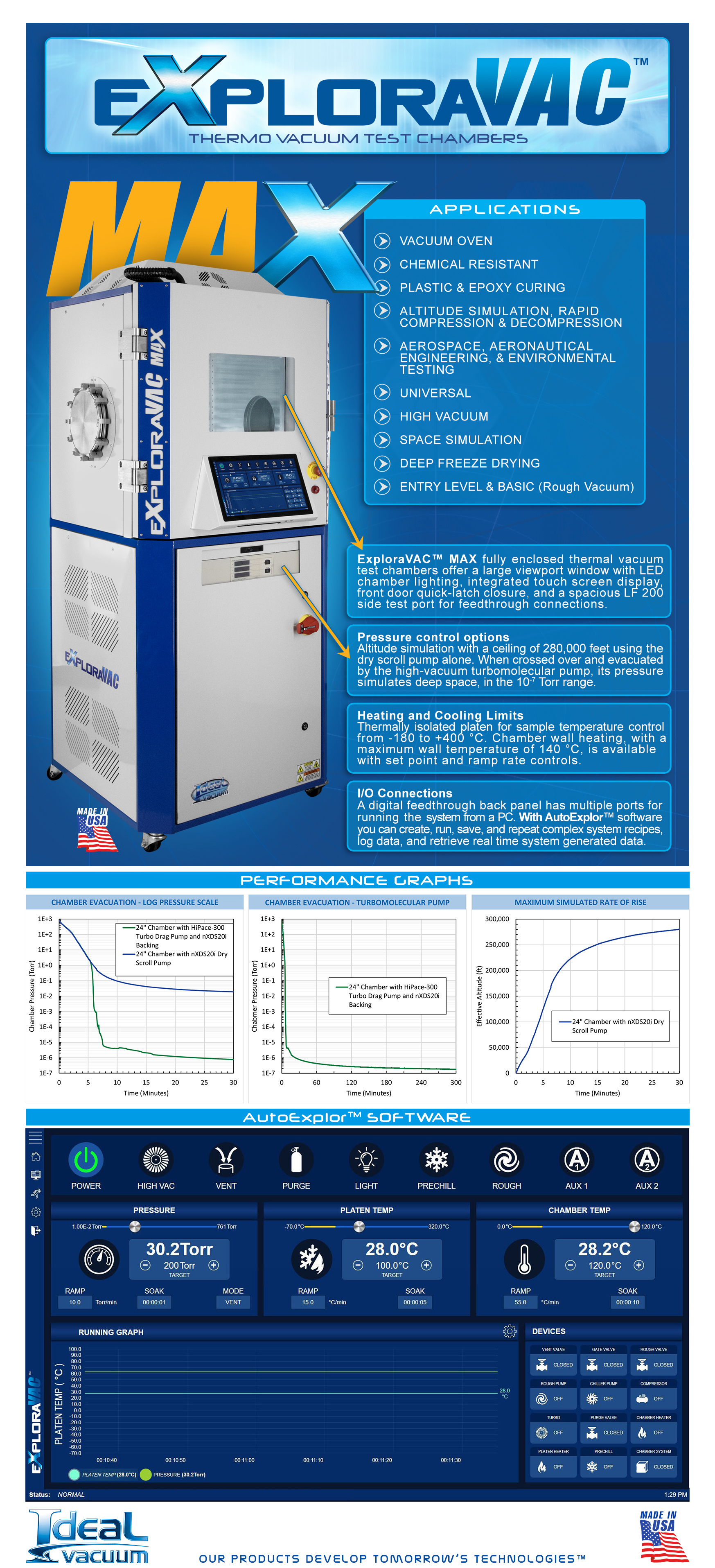

See the performance graph PDF download below for all option's performance data.

ExploraVAC Space Simulation System Configuration:

- 24 Inch Cube Welded Stainless Steel Chamber

- Stainless Steel Front Chamber Door

- Purge Ports

- Heated and Cooled Platen

- Platen Temperature Range: -70°C to +225°C

- Platen Ramp Rate: 3.5°C/min heating, 3°C/min cooling

- Pfeiffer HiPace 300 Turbomolecular Pump

- Edwards nXR30i Dry Roots Vacuum Pump

- QTY2 LF-200 Side Ports (Allow for a variety of feedthroughs to be added from either side of the chamber)

The

ExploraVAC series of TVAC thermal vacuum chamber process and test instruments create precise environments empowering the operator with complete control over internal chamber pressure and temperature. They are built with innovation in mind. They allow for prototype device exploration in vacuum during the product research and development phase and for precise process control in small batch processing. These thermal vacuum test chamber instruments are designed to allow users to quickly tailor experiments to gather product analysis and diagnostics data as the product is subjected to the extreme stress factors of vacuum and temperature.

ExploraVAC TVAC thermal vacuum test chambers are completely configurable with many available system options (see product configurator above).

ExploraVAC System Configuration Options:

- Roughing Pump (dry scroll or dry multi-stage roots, various speeds)

- High Vacuum (various speeds)

- Full Vacuum Pressure Control

- Heated and Cooled Platen

- Chamber Wall Heating

- Integrated Chamber Lighting

- Closed-Loop Refrigerated or LN2Cryogenic Cooling System

- Automated Software Control

- Remote Control Operation

- Purge Ports, Chamber Shelving, and Much More

A large selection of vacuum chambers are available for

ExploraVAC, including welded stainless steel chambers with (internal) cubic sizes (12, 16, 20, or 24 inch) or Ideal Vacuum Cube™ modular chambers with (internal) cubic sizes (9, 12, or 24 inch). Chambers can be configured with aluminum or stainless steel doors, with or without viewports.

The

ExploraVAC TVAC system cabinet has a conveniently angled front panel control surface with colored LED pushbutton interface which controls all chamber functions. PID controllers and gauges are installed as required for user selected options. A PLC manages system functions including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage. The front accessible, built-in NEMA style enclosure houses the electronics needed for system operation.

A spacious LF-200 side port is available for user-selected or designed accessories, such as an electronic feedthrough for device monitoring or shock testing, an infrared lamp array for radiant heating or temperature differential tests, or an ultraviolet lamp array for ionizing radiation tests. This system could be customized to obtain any desired rate of rise by adding additional vacuum pumps mounted outside the cabinet.

The back of the cabinet holds a bulkhead feedthrough panel for chamber venting, pump exhaust, and the purge gas option. A digital feedthrough back panel has multiple ports including a DB9 connector for running the system remotely from a workstation or laptop running Microsoft Windows 10 or 11 with our

AutoExplor™ software.

The (non-expiring) basic version of

AutoExplor (P1012102) allows a user to manually control devices while protecting the system.

AutoExplor properly sequences pumps and automatically operates the correct valves for a given request. The user can program pressure and temperature setpoints, ramp rates, soak times, and venting (if the system is equipped with those hardware options). The software provides real-time graphical data streaming so the user can visualize system behavior.

AutoExplor maintains an internal preventive maintenance schedule and notifies the user when system service is due. For example, it notifies when scroll pump tip-seal replacements are needed and when sensor calibration is due. This helps keep the system at peak operating performance. It also provides fault and error messages along with specific troubleshooting information in the case of a device failure so that the issue can be corrected as soon as possible.

The premium version of

AutoExplor (P1012100) includes all the features of the basic software package (above) and adds automated recipe control, data logging, and log export capabilities. Complex test recipes can be created as a step-by-step process, where each step can control the on/off state, setpoints, and ramp rates of multiple devices. One or multiple end conditions for each recipe step may be set using logical operators. The premium version allows the user to quickly generate environmental TVAC test reports from recipe data log files. Logs can be reviewed to ensure targeted process parameters are achieved. The premium version also includes

AutoExplor IP Client, which gives the software the ability to be used as a host that can manage multiple external network clients, and

AutoExplor API (application programming interface), which allows a scientist or programmer to integrate an

ExploraVac instrument into their existing software test suite without using

AutoExplor’s software interface. The premium version must be renewed annually or it reverts to the basic version.

The

ExploraVAC series of TVAC pressure and temperature-controlled test chambers are a perfect solution for many product testing requirements.

Sample Applications

- Environmental Testing Chamber

- Altitude Test Chamber

- Space Simulation Test Chamber

- Thermal Shock Chamber

- Aerospace & Aeronautical Engineering Test Chamber

- High Altitude Flight Component Testing

- Vacuum Oven

- Vacuum Freeze Drying

- Plastic & Epoxy Curing & Outgassing

About Space Simulation:

The conditions felt in space are extreme. Satellites, CubeSats, and spacecraft experience constant high vacuum and large temperature swings during the day-night cycle as they pass into the suns unfiltered rays and then into the earth’s cold shadow. For example, an object in low earth orbit without temperature regulation mechanisms may reach -170 °C in the night and 123 °C in the day. Due to the high cost of launching an object into space, it is crucial, and often mandatory, to rigorously test all individual components and the entire assembled device before deployment.

Ideal Vacuum’s

ExploraVAC Space Simulation TVAC thermal vacuum system has a 24 inch cubic chamber which can fit most individual components, a small commercial satellite, or a 12U CubeSat. The built-in Pfeiffer HiPace 300 turbomolecular pump delivers pressures down to 1 × 10

-7 Torr to effectively simulate deep space. This matches most space simulation requirements and far exceeds the standard CubeSat testing requirement of 1 ×10

-3 Torr. The heated and cooled platen allows precise sample temperature control from -70 °C to 400 °C with ramp rate and setpoint control accurate to ± 0.3 °C. These extreme temperatures allow light-shadow thermal temperature cycling tests or thermal vacuum outgassing tests. Clean inert gas can be introduced into the chamber through the purge port after each vacuum cycle to improve system cleanliness and purity. The spacious LF-200 side port can be used for accessories, such as an electronic feedthrough for device monitoring or shock testing, an infrared lamp array for radiant heating or temperature differential tests, or an ultraviolet lamp array for ionizing radiation tests.

This system can be further upgraded with pressure control if the objects being tested may experience variable pressures on their way to space.

For even faster and deeper cryogenic cooling (down to -170 °C), our XtremeFreez recirculating liquid nitrogen cooling option allows simulation of even colder space temperatures or for thermal shock testing.