ExploraVAC Unlimited: Elevating Thermal Vacuum Simulation Chambers to Unprecedented Heights

In the dynamic realm of space and aerospace industries, precision and reliability are paramount. Enter ExploraVAC Unlimited, the pinnacle of Thermal Vacuum Simulation Chamber Systems designed to meet the rigorous demands of your technical endeavors.

Call Today To Configure Your Own Custom System and Get a Price

Detailed System Overview

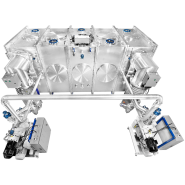

This ExploraVac UNLIMITED system, is a custom-built thermal vacuum environmental chamber. The vacuum chamber is 6 ft. x 6 ft. x 15 ft. internally and made up of five welded 304 stainless steel sections with a volume of 540 ft^3 . The chamber is engineered so that additional 3' deep sections can be added to increase its depth. The chamber has ceiling mounted illuminated viewing windows and numerous large blanked ISO-500 and ISO-630 blanked ports. It is equipped with a variety of smaller KF, ISO-K, and CF (Conflat) feedthrough ports for sensors, gauges, thermocouples and specialty customer equipment.

Two Leybold SV320B/WAU-1001 rotary vane/roots blower roughing pump packages provide fast rough vacuum, and two Agilent HS-20 diffusion pumps with cold caps (halos) and using DC704 silicone oil provide high vacuum capability. This redundancy provides fast cycle times and allows a roughing pump package or diffusion pump to be taken offline for service or replacement while the rest of the system continues to operate. A smaller rotary vane pump is used to back the diffusion pumps when the chamber is opened.

IVP’s Super-Seal and ULTRALock pneumatic valves are used to direct vacuum flow. IVP’s CommandValve electronic butterfly throttle valves are used for controlled purge gas injection or chamber venting. They allow the chamber to vary or maintain precise chamber pressures for experiments such as altitude simulation. The system has multiple roughing and high vacuum gauges (sensors) located on the chamber and in the vacuum lines. An Agilent XGS-600 gauge controller collects sensor data and sends it to the control console where it is used to operate and monitor all aspects of the system. System functions, including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage are managed by a PLC located in the control console.

All necessary equipment, such as valves, gauges, sensors, and necessary plumbing are included. Customer supplied compressed air (70 psi minimum) is required. The system is controlled from a touch screen display running our proprietary AutoExplor software for Windows. The system comes with removable chamber door locks to prevent personnel entrapment along with a keyed emergency switch. System electrical lockout/tagout is necessary prior to anyone entering the chamber.

ExploraVAC Unlimited Overview

ExploraVAC Unlimited is a turnkey solution, meticulously designed to streamline your operations from the moment of installation. With comprehensive integration of all essential components and systems, including pumping, instrumentation, and thermal control, each unit arrives fully equipped and ready to run. Our commitment to a productive user experience means that from the outset, customers can dive into their experiments with confidence, knowing that every element necessary for vacuum system operation is seamlessly integrated and optimized for performance.

From aerospace to semiconductor industries, our chambers cater to diverse applications including altitude simulation, rapid decompression, and thermal cycling, providing the ultimate solution for your simulation needs. With a range spanning from +6psig* to high vacuum, and temperatures from -170°C to +400°C, ExploraVAC Unlimited offers limitless possibilities for your experiments.

AutoExplor Premium Software

With an intuitive touchscreen interface, the AutoExplor system control empowers users to orchestrate complex simulations effortlessly. Streamlining operation and ensuring safety, AutoExplor's automated control features simplify experimentation, while its compatibility with external systems like LabView enhances flexibility. With recipe building, data logging, and remote access capabilities, AutoExplor maximizes efficiency and convenience in thermal vacuum simulation.

Flexible Vacuum Chamber Design

The modular architecture of Ideal Vacuum's sectional vacuum chambers offers a space-efficient rectangular footprint with customizable width, height, depth, and configuration. Our stainless steel chambers are carefully fabricated with quality materials and components, and mechanically polished for peak vacuum performance. With integrated stands, single/double/pullout access doors, customizable ports, and payload fixturing options, every aspect of our chambers is engineered for convenience and adaptability to your unique requirements.

Integrated Vacuum Pumping System

Our optimized pumping systems boast integrated control valve packages with automated control, ensuring unparalleled efficiency and safety. With both wet and dry low/high vacuum solutions available, our diverse selection of pumping packages guarantees your system can deliver the vacuum performance you need.

ExploraVAC Unlimited Dry

For ultimate clean pumping performance, dry rough vacuum pumping packages feature a dry screw type pump, coupled with a roots blower booster pump on high-output configurations. Dry pumps feature zero oil backstreaming and do not require oil servicing during their life. For dry high vacuum systems, both turbomolecular and cryo type pumps are available for ultimate pressure performance down to 10e-8 torr.

ExploraVAC Unlimited Wet

Wet rough vacuum pumping packages feature a rotary vane type pump, coupled with a roots blower booster pump. On rough vacuum systems without diffusion pumps, some oil backstreaming may occur at pressures below 0.1 torr. Diffusion type high vacuum pumps are available on wet systems for pressures down to 10e-7 torr. Wet pumping systems have a lower cost compared to dry pumping systems, and diffusion pumps do not require time-intensive regeneration seen with cryo type high vacuum pumps.

Thermal Platens and Shrouds

ExploraVAC Unlimited's thermal platens and shrouds epitomize cutting-edge thermal management. Our platens offer single or dual-surface thermal control, coupled with options for resistive heating and circulated cooling to ensure precise temperature regulation. Paired seamlessly with LN2 or Huber chilling systems, our systems can achieve optimal thermal uniformity and rapid ramping. Meanwhile, our thermal shrouds provide full surround coverage, controlling radiative heat transfer with advanced coatings. With various cooling power units available and a lightweight design for swift thermal ramping, our platens and shrouds set the standard for thermal performance in the space and aerospace industry.

System Instrumentation

We provide our users with several choices in vacuum measurement gauges to match budget, measurement range, and precision requirements. From inexpensive convective rough vacuum gauges to precise cold cathode high vacuum gauges, our instrumentation suite has the right options for your needs. Integrated and expandable thermocouple channels support thermal operations, while onboard equipment health monitoring and alerts provide comprehensive insight into system performance.

ExploraVAC Unlimited is a gateway to innovation, reliability, and unparalleled performance in the realm of thermal vacuum simulation. Elevate your experiments, transcend boundaries, and explore the cosmos with confidence, powered by ExploraVAC Unlimited.

*Depending on chamber size and configuration

How is ExploraVAC Unlimited different from ExploraVAC Standard?